| Container type | Height | Opening diameter | Thickness |

|---|---|---|---|

| 400 g Metal Can | 100.9mm | 73mm | 0.16mm |

| Simple lid of 400 g Metal Can | 73mm | 0.18mm |

| Container type | Height | Opening diameter | Thickness |

|---|---|---|---|

| 800 g Metal Can | 108.8mm | 99mm | 0.21mm |

| Simple lid of 800 g Metal Can | 99mm | 0.21mm |

It stands for In Mold Labeling.These type of labels are inseparable from the container.

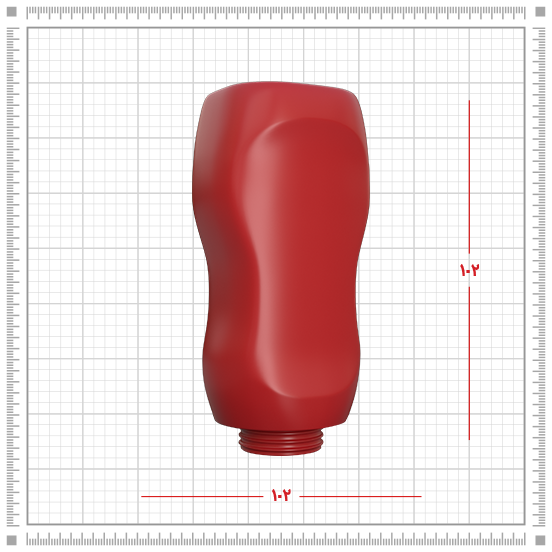

| Container type | Dimensions (mm) | Weight (g) |

|---|---|---|

| 250 g Container | 102×102 (±3)×49(±2) | 13.5±5% |

| 250 g Cap | 98×98 (±2) | 8±10% |

| 400 g Classic container | 134×101×49(±2) | 20±10% |

| 400 g Classic cap | 131×98 (±2) | 11±10% |

| 880 g Container | 188×127×58 (±2) | 37.4±3.5% |

| 880 g Cap | 187×126 (±2) | 17.5(+10%-5%) |

| 400 g Traditional container | 132×90×60 (±2) | 14±5 |

| 400 g traditional cap | 136×92×28 (±2) | 10.5±5% |

| 3500 g Container | 292×242×67 (±2) | 110±3.5% |

| 3500 g Cap | 293×243 (±3) | 61±2% |

| Container type | PCO diameter (mm) | Weight (g) |

|---|---|---|

| Can Cap | 99mm | (±0/5)6 gr |

| PCO | Weight (g) | Thickness (mm) | Total Height (mm) | PCO Height (mm) | PCO Diameter (mm) | Preform Diameter(mm) | Number Per Bag |

|---|---|---|---|---|---|---|---|

| 29/25 | 14/03±0/1 | 2.45±0.1 | 80 | 12.6±0.15 | 25.1±0.12 | 21.44 | 1000 |

| PCO | Weight (g) | Thickness (mm) | Total Height (mm) | PCO Height (mm) | PCO Diameter (mm) | Preform Diameter(mm) | Number Per Bag |

|---|---|---|---|---|---|---|---|

| 30/25 | 17±0.1 | 2.5±0.1 | 85 | 18.5±0.15 | 25.1±0.12 | 21.45 | 1000 |

| 34±0.2 | 2.5±0.1 | 132 | 18.5±0.15 | 25.1±0.12 | 27 | 500 |

| PCO | Weight (g) | Thickness (mm) | Total Height (mm) | PCO Height (mm) | PCO Diameter (mm) | Preform Diameter(mm) | Number Per Bag |

|---|---|---|---|---|---|---|---|

| PCO 28 | 22±0/3 | 4±0.2 | 90 | 21.01±0.25 | 21.74±0.13 | 22.68 | 1000 |

| PCO 28 | 45/05±0/5 | 3.2±0.2 | 150 | 21.01±0.25 | 21.74±0.13 | 26.60 | 500 |

| PCO 28 | 17±0/3 | 2.6±0.02 | 81 | 21.01±0.25 | 21.74±0.13 | 22.68 | 1000 |

Dimensions and specifications according to customer order

This production unit is capable of producing all kinds of injectable polymer containers with polyethylene and polypropylene raw materials as well as producing all types of PET bottles at a speed of 8000 pieces per hour. The pneumatic machine for producing polyethylene and polypropylene bottles is capable of manufacturing a variety of bottles, customized according to customer needs (for milk, sauce, etc.).

No. 15 , Masjed Jame ghadir khom St., 4th Negarestan Alley, Pasdaran Ave., Tehran-Iran

Tel: 02191008895

Tel: 02122888890

E-mail: info@rojintaak.com

Postal code : 1664713561

7th km of Sarableh road, Ghazanchi junc, Kermanshah, Iran

Tel: 08337106936

E-mail: info@rojintaak.com

Postal code : 6738141111

All right reserved By: rojintaak

Design & Developed By:

All right reserved By: rojintaak

Design & Developed By: